Concrete Pump Truck

Concrete placing boom

Concrete Pump

Mixer Truck

Wear-resistant pipeline

Concrete Pump Accessories

PM Schwing CIFA Accessories

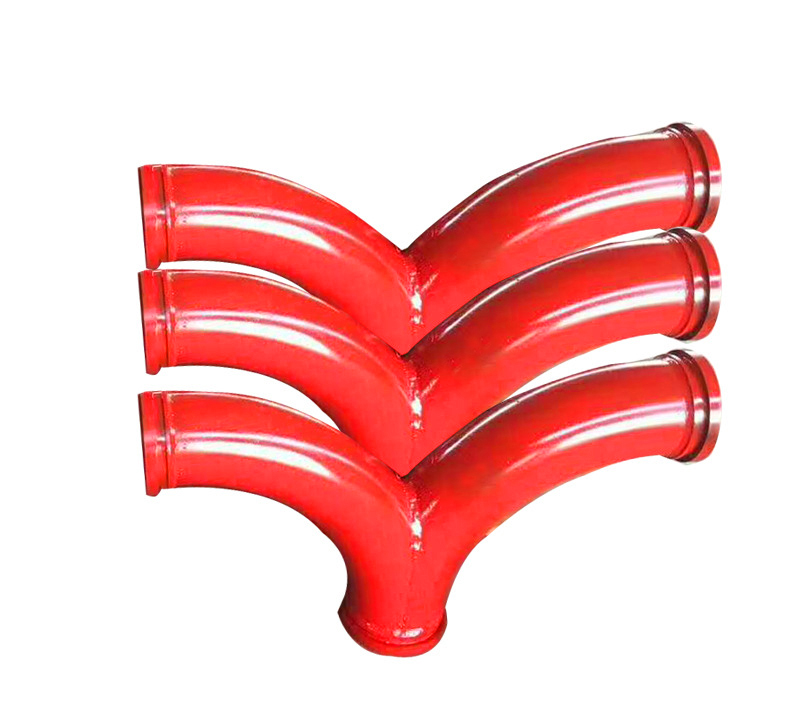

Elbow

Power Elbow Tee

-

Name:

-

Description:Elbow is a commonly used connecting pipe fitting in plumbing installation. It is used for the connection at the bend of t..

JIDA heavy industries power elbow, reducing elbow and tee:

Elbow is a commonly used connecting pipe fitting in plumbing installation. It is used for the connection at the bend of the pipeline and to change the direction of the pipeline.

Other names: 90 ° elbow, right angle bend, love bend, stamping elbow, pressing elbow, mechanism elbow, welding elbow, etc.

Purpose: connect two pipes with the same or different nominal diameter to make the pipeline turn 90 °, 45 °, 180 ° and various degrees.

Bending radius less than or equal to 1.5 times of pipe diameter belongs to elbow, and bending radius greater than 1.5 times of pipe diameter belongs to elbow

Purpose:

A connecting pipe fitting commonly used in pipeline installation, which connects two pipes with the same or different nominal diameter to make the pipeline turn at an angle, and the nominal pressure is 1-1.6mpa.

Technical requirements:

1. Since most of the pipe fittings are used for welding, in order to improve the welding quality, the ends are turned into grooves, with appropriate angles and appropriate edges. This requirement is also strict. The thickness of the edges, the angle and the deviation range are specified. The surface quality and mechanical properties are basically the same as those of pipes. For the convenience of welding, the steel grade of pipe fittings and connected pipes is the same.

2. That is, all pipe fittings shall be subject to surface treatment, and the iron oxide scale on the internal and external surfaces shall be sprayed off by shot peening, and then painted. This is for export needs. Moreover, this work should be done at home to facilitate transportation and prevent corrosion and oxidation.

3. It is the requirement for packaging. For small pipe fittings, such as export, wooden boxes need to be made, about 1m3. It is stipulated that the number of elbows in such boxes can not exceed one ton. The standard allows suits, that is, large sets and small sets, but the total weight can not exceed 1 ton. For large pieces y, a single package is required, such as 24 ″ single package. The other is the packaging mark, which should indicate the size, steel number, batch number, manufacturer's trademark, etc.

Classification:

Divided by material

Carbon steel: ASTM / ASME a234 WPB, WPC

Alloy: ASTM / ASME a234 WP 1-wp 12-wp 11-wp 22-wp 5-wp 91-wp911, 15Mo3, 15CrMoV, 35crmov

Stainless steel: ASTM / ASME A403 WP 304-304l-304h-304ln-304n

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Low temperature steel: ASTM / ASME A402 wpl3-wpl 6

Steel: ASTM / ASME a860 wphy 42-46-52-60-65-70

Cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon, PVC, PPR, rfpp (reinforced polypropylene), etc.

Divided by manufacturing methods, it can be divided into pushing, pressing, forging, casting, etc.

Divided by manufacturing standards, it can be divided into national standards, electrical standards, ship standards, chemical standards, water standards, American standards, German standards, Japanese standards, Russian standards, etc.

According to its radius of curvature: it can be divided into long radius elbow and short radius elbow. Long radius elbow refers to the outer diameter of the pipe whose radius of curvature is equal to 1.5 times, i.e. r = 1.5D; Short radius elbow means that its radius of curvature is equal to the outer diameter of the pipe, i.e. r = 1.0d( D is the elbow diameter and R is the radius of curvature).

According to the pressure level, there are about 17 kinds, including: sch5s, sch10s, sch10, sch20, sch30, sch40s, STD, sch40, sch60, sch80s and XS; Sch80、SCH100、Sch120、Sch140、Sch160、XXS; STD and XS are commonly used.

According to different shapes and uses, it can be divided into: groove elbow, ferrule elbow, double socket elbow, flange elbow, reducing elbow, stay seat elbow, internal and external tooth elbow, stamping elbow, push elbow, socket elbow, butt welding elbow, internal wire elbow, etc.

- prev:Elbow

- next:none

Company Dynamics

News

Copyright © 2019 - 2020 Jida Heavy Industries All Right Reserved.